Damage to pipelines on seabed can occur from fishing nets, anchors, wrecks, scaffolding or because of conformation and seafloor sediment motion (seabottom currents and tidal currents).

The Hydraulic Smart Flange (HSF) connectors work hydraulically, they are used to seal the pipes before carrying out repair tasks. HSFs are installed by divers or operators with an ADS systems in shallow and deep water and they can be operated by ROV. HSFs are equipped with elastomeric seals that provide containment of fluid spilled and two half cylindrical hull sections equipped with flanges, which are bolted together around the damage on the pipeline or riser.

To obtain the right seal it is necessary to create a tension on stud bolts which operate a piston and which compresses an elastomeric seal on the pipe. HSFs have a maximum stroke indicator or red band which becomes visible when the piston is at maximum stroke, in which case the pump must be stopped immediately. The HSFs sealing and gripping mechanisms are activated by hydraulic pressure. The flange, tensioners and hoses should be placed by divers, then the pump delivery will be adjusted to start pressurization.

The range includes various size options and all models are suitable for high operating pressures. They are designed for quick and accurate tensioning of pipe flanges.

The HSF is lowered by crane and subsequently installed by divers or ROVs. Many of these HSFs can be modified for ROV installation quickly.

pipeline or topside/onshore pipework, providing a quick, easy and

cost effective solution

Mechanical and joint assurance specialist, Hydratight, offers stateoftheart clamps such as the Adaptable MORSEAL Pipe Clamp. It is deployed to repair a leaking subsea pipeline or topside and onshore pipework, providing a quick, easy and cost-effective repair solution to ensure asset integrity is maintained.

The installation of these devices in shallow water is carried out by divers while the operations in deep water are completed using a work-class ROV. In both cases the procedure is similar, it is necessary to turn the bolts by hand or with special equipment (torque wrench or tool) as long as the seals are properly in place.

Before the HSF is placed on the wear and damaged part of the pipe, the diver or ROV intervention include the excavation task around the pipe to facilitate the installation of the device, thoroughly clean the pipe surface and inspect for defects (protrusions, excessive corrosion) to assure maximum sealing.

Upon completion of the HSF installation the divers or ROV can place sandbags or grouths under the device to prevent the collapse of the pipeline due to weight of HSF.

Read more in the digital JP Mag – JPmag – October 2021

Paolo Mazzone

SubEng – HSE Adviser

MORSEAL Pipe Clamp by Hydratight

Atmospheric Diving Suit – Special articulated and submersible armour that allows one operator to perform dives while maintaining the inner pressure of one atmosphere.

WASP at the OSEL Testing tank Gt Yarmouth, UK – By Osel979, from wikimedia commons.

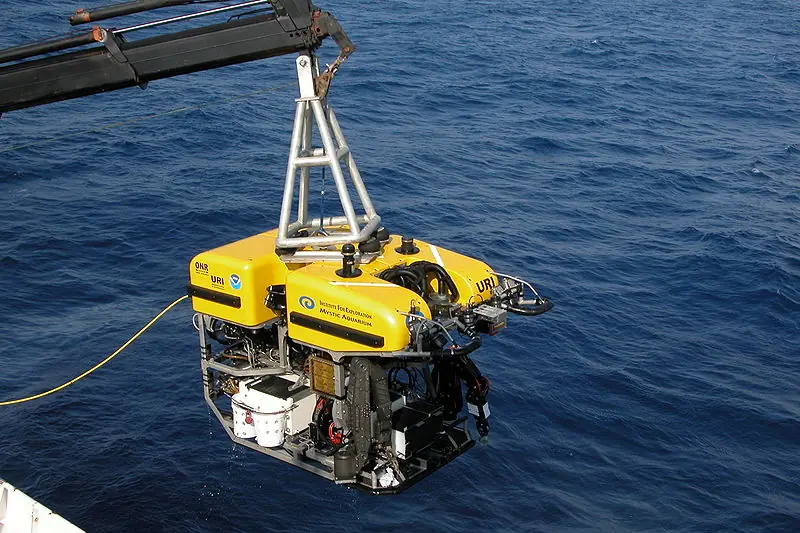

Remotely Operated Vehicles – Special submarine vehicle that is connected to the surface with an umbilical. The ROV is an unmanned vehicle, controlled by pilots and allows them to see what’s happening underwater and to interact with objects, if it is equipped with a manipulator.

An ROV can be equipped with different tools and devices, such as cameras, sonar systems, NDT equipments, manupilators, etc.

ROV ‘Hercules’, by Brennanphillips from wikipedia.

Cover: JP Mag – diver works on HSF device