Coronavirus has brought the future closer: the use of robots has become a reality in many industries. In the era of pandemic, robots and unmanned systems are used to replace workers at home and to increase social distancing. The industrialized world in the near future will see an impact on the workplace, which will lead to a reduction in the demand for workers for highly qualified employees. Many employees are adverse towards robots, although robots are an essential factor without which some industries and services could not exist.

Robots already undertakes tasks such as driving, conversational, diagnosing medical conditions, food preparation, manufacturing, material handling, automotive applications, assembly work, inspection and testing process, construction, transportation and logistics.

Due to today’s highly competitive environment and the rapid change caused by technical development, employees should always be willing to learn new skills. Future employees must learn new qualifications, attend courses and specializations, because worker’s task it is not necessary only to oversee robots and unmanned systems, but also to coordinate them.

Training institutes have a great responsibility, they should reconfigure and upgrade their teaching system to teach candidates as the job will be and not as it was.

Indeed with the rise of robots and unmanned systems new jobs are created, such as: data processing and scientist, crowdworkers, computer scientists, software engineers, application developers and programmers, maintenance managers/plant managers, robot coordinator, including electricians, mechanics and industrial technicians, pilots and operators, wearable tech designer, data security expert, digital investigations and eDiscovery, software and hardware engineers. These professionals (and the ones who will come!) have a role to play in this area of technology.

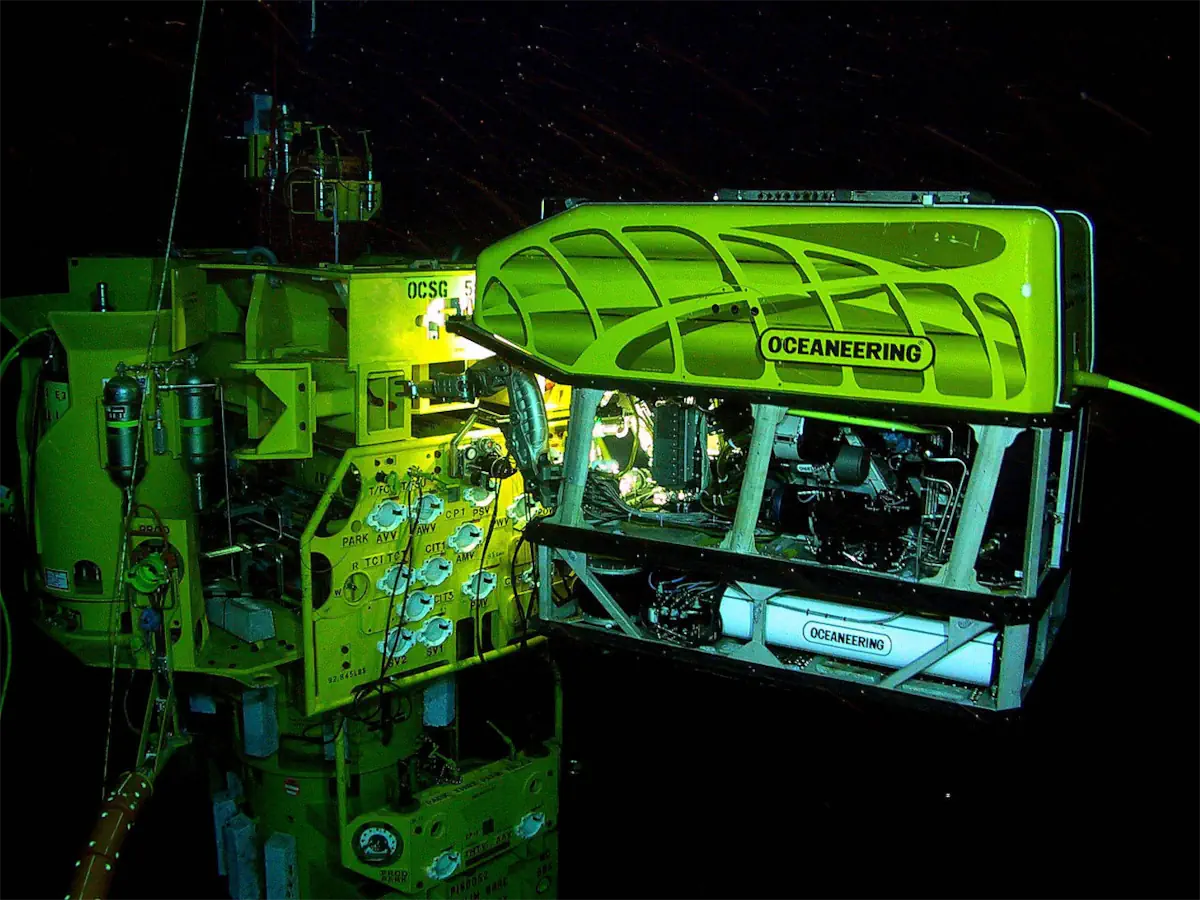

Workers in Offshore oil fields and wind farm facilities face more risks than in most other places.

To improve Health and Safety, avoid risk exposure and lower environmental impact, it has been growing the use of autonomous or remotely controlled robots and systems.

The history of unmanned vehicles in the Oil and Gas or Renewable Energy sector stretches back a few years ago. The ROVs (Remotely Operated vehicles) and AUVs (Autonomous Underwater Vehicles) have been used to eliminate the need to send divers down to perform underwater tasks at often dangerous depths and conditions.

There are other types of robots and Unmanned vehicles depending on their field of operation, which can be deployed in different domains of Offshore energy: Unmanned Aerial Vehicles (UAVs), Unmanned Ground Vehicles (UGVs), Unmanned Surface Vehicle (USVs). They are being used in a wide range of applications, subsea, marine surface, onboard rig and platform, for transport and logistics.

The use of robots is changing the world, they will change every aspect of our lives and will continue to do so in ways we can only imagine.

Jessica Moro

DSO

Images:

Post cover: Human-Robot-Collaboration-Sawing-2016-Luka-Peternel – By Luka Peternel –https://commons.wikimedia.org/wiki/File:Human-Robot-Collaboration-Sawing-2016-Luka-Peternel.jpg – Collaborative human-robot sawing experiment performed at Italian Institute of Technology in 2016

Article: 1280px-ROV_working_on_a_subsea_structure.jpg – By Mierlo – https://en.wikipedia.org/w/index.php?title=File:ROV_working_on_a_subsea_structure.jpg – This pictures was uploaded by Frank van Mierlo. It was generously donated to the public domain by the Vice President of Oceaneering Mr. Duncan McLean